| Material: | Bronze, C17200, C17000 | Shape: | Coil/ Tape/ Strip |

|---|---|---|---|

| Common Name: | C17200, C17000 | Application: | Electronic |

| Thickness: | 0.005- 2.5mm | Surface: | No.1,2B,BA,No.4,Mirror |

| Highlight: |

copper alloys, copper nickel alloy |

||

Nickel Plated Beryllium Copper Alloy High Strength C1720/C17200

Beryllium cooper strip is widely used in producing all kinds of micromotor’s brush, switch, relay, cell phone battery, spring,connector, attemperator’s leaf spring which with high strength, high elasticity, high hardness and high wearing feature.

Features:

1. Strength: by age-hardening, can reach up to 1500N/mm2 tensile strength, so it be used as elastic material which can tolerate high bending stress.

2. Electrical conductivity: According to different alloys, specification, about 20-70% IASC (international annealed copper standard) can be used as high density voltaic elastic material.

3. Machinability: Before age hardening, the material can be complicated formed processing.

4. Fatigue Strength: Have excellent anti-fatigue properties(Can be operate repeatedly), so be widely used in long-life and high-reliability accessories.

5. Heat resisting property: Can keep small Stress relaxation rate in the high temperature condition, so can be used under a large temperature range.

6. Corrosion resistance: In range of all copper alloy, it has better corrosion resistance than Copper-Nickel Alloy,scarcely initiate corrosion by environmental implication.

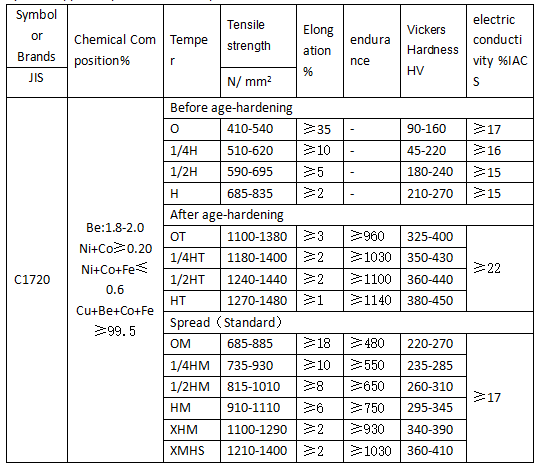

Beryllium copper strip Mechanical Properties